Constructing a barn is a significant investment. It requires careful planning, informed decision-making, and an understanding of various materials. One crucial factor that is often overlooked but immensely important is steel gauge. This refers to the thickness of the steel sheets used in the construction of your barn. Choosing the correct steel gauge can mean the difference between a barn that stands the test of time and one that suffers from early wear and tear. Understanding what steel gauge is and how it impacts your barn’s strength can help you make more informed and cost-effective decisions.

What Is Steel Gauge?

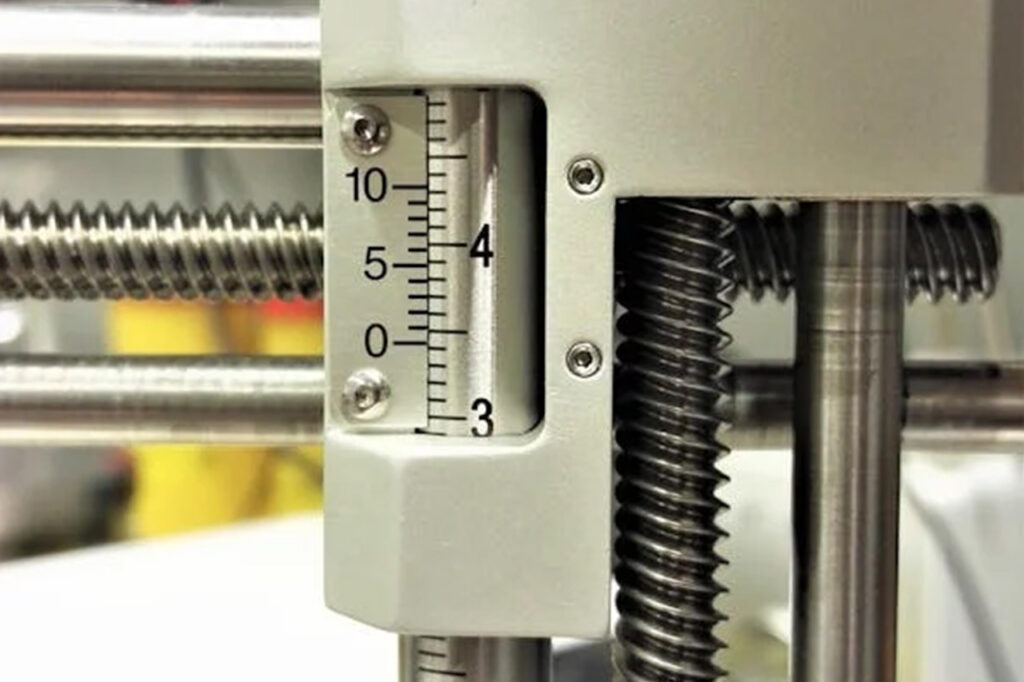

Steel gauge is a unit of measurement that refers to the thickness of a piece of steel. Unlike most measurement systems, in the steel gauge system, the lower the number, the thicker the steel. For instance, 12-gauge steel is much thicker than 29-gauge steel. The system was developed based on the number of operations required to produce a specific thickness. Over time, it became standardized and is now commonly used in the construction and manufacturing industries.

This inverse relationship between number and thickness can be confusing, but it is critical to understand when selecting materials for your barn. A simple rule to remember is that lower gauge numbers signify stronger, more durable steel. The gauge you choose affects the structural integrity of the building, its resistance to weather conditions, and its long-term durability.

Common Steel Gauges in Barn Construction

Different parts of a barn require different steel gauges based on their function. Structural components such as frames and supports typically use lower gauge steel for added strength. For instance, 12-gauge and 14-gauge steel are commonly used for the main framework. These thicker sheets provide a strong foundation and support for the entire structure.

On the other hand, siding and roofing often use higher gauge steel such as 26 or 29 gauge. These sheets are thinner and lighter, making them easier to install and cost-effective. However, their reduced thickness means they offer less protection against external elements compared to lower gauge steel.

How Steel Gauge Impacts Strength

The strength of a barn heavily depends on the steel gauge used. Thicker steel provides more resistance against physical stress, weather extremes, and long-term wear. For example, a barn built with 12-gauge steel will be significantly more durable and stable than one constructed with 29-gauge steel.

Thicker steel can bear more weight and resist deformation. This is especially important for areas prone to heavy snow, strong winds, or where the barn will house large animals or heavy equipment. A thicker gauge helps ensure the barn can support these additional loads without bending or breaking.

Climate and Environmental Considerations

The climate in which your barn will be located plays a big role in determining the appropriate steel gauge. In areas with high snowfall, thicker steel is essential to support the weight of accumulated snow. In regions prone to strong winds or hurricanes, lower gauge steel offers the structural strength needed to withstand such forces.

Humid or coastal environments present another challenge. Moisture and salty air can accelerate the corrosion of metal structures. Thicker steel not only provides a more substantial barrier but also allows for better coating and treatment options to resist rust. In these cases, using a lower gauge steel can significantly extend the life of your barn.

Cost vs. Longevity

Choosing a lower gauge steel means a higher upfront cost. Thicker steel is more expensive due to the increased material and handling requirements. However, this initial investment often pays off in the long term.

Lower maintenance, fewer repairs, and a longer lifespan contribute to the overall cost-effectiveness of using thicker steel. A barn built with 12-gauge steel may last decades longer than one made with 29-gauge steel. This makes it a smart investment, particularly for those planning to use the barn for livestock, expensive equipment, or as a long-term structure.

Installation and Labor Considerations

Using thicker steel can impact the installation process. Thicker sheets are heavier and may require specialized equipment and skilled labor for proper handling and fitting. This can increase the overall labor cost and time required for construction.

However, once installed, thicker steel tends to require less maintenance. It is less likely to dent, warp, or develop leaks. This makes it a more convenient and reliable option in the long run, particularly for larger or more complex barn designs.

Building Codes and Local Regulations

Different regions have varying building codes and regulations that dictate the minimum steel gauge for specific structures. These regulations are based on local climate conditions, typical building use, and safety standards. Using the appropriate steel gauge ensures compliance with these codes, which can simplify the permitting process and prevent potential legal issues.

Failure to meet local requirements can result in fines, delays, or even the need to rebuild. Consulting with local building authorities or a professional contractor can help you choose the correct gauge and avoid these complications.

Resale and Property Value

A barn built with lower gauge steel can add more value to your property. Potential buyers or future users of the property will recognize the durability and strength of the structure. This can make your property more attractive and potentially increase its market value.

Moreover, a high-quality barn with proper materials can enhance the overall aesthetics of your property. It stands as a testament to good craftsmanship and attention to detail, further boosting its appeal and functional worth.

Energy Efficiency and Insulation

Thicker steel can also improve the energy efficiency of your barn. It provides a more stable structure that better supports insulation materials. This helps maintain internal temperatures, reducing the need for heating or cooling and lowering energy costs.

In climates with extreme temperatures, this can make a significant difference in comfort levels for both animals and people using the barn. Proper insulation supported by durable steel can turn a basic structure into a year-round usable facility.

Noise Reduction

Lower gauge steel has better sound-dampening qualities. It reduces the amount of noise that penetrates the structure from the outside. This can be beneficial in noisy environments or when housing sensitive livestock. A quieter barn contributes to a more comfortable and less stressful environment.

Inside the barn, thicker steel also reduces the echo effect, making conversations and work inside the structure more manageable. This might not seem like a major consideration at first, but it becomes important in daily use.

Customization and Design Flexibility

Thicker steel allows for greater flexibility in design. It can support additional architectural features such as mezzanines, heavy-duty doors, and specialized roofing systems. This makes it a suitable choice for barns that serve multiple purposes.

From housing livestock to storing equipment or functioning as a workspace, a barn built with lower gauge steel can be adapted to meet changing needs over time. This flexibility ensures your investment remains useful and relevant for years.

Resistance to Fire and Pests

Steel, in general, offers excellent resistance to fire and pests compared to wood. Thicker steel enhances these protective qualities. It takes longer to warp or fail under high temperatures, giving firefighters more time to respond in the event of a fire.

Thicker steel also provides fewer entry points for pests such as rodents and insects. This can help in maintaining the hygiene and cleanliness of the barn, which is especially important when storing feed or housing animals.

Long-Term Maintenance Benefits

One of the biggest advantages of using lower gauge steel is the reduction in long-term maintenance. Thicker steel is more resistant to the common issues that plague thinner sheets, such as dents, rust, and surface degradation.

Routine inspections become less burdensome, and repairs are less frequent. When repairs are needed, thicker steel provides a more stable base for patches or welding, making the process simpler and more effective.

Choosing the Right Gauge for Your Needs

Selecting the correct steel gauge depends on several factors including your location, intended barn use, budget, and long-term plans. For most structural components, 12-gauge steel offers a high level of strength and reliability. For roofing and siding, 26-gauge steel provides a good balance between cost and performance.

Consulting with a knowledgeable builder or supplier can help you make the best choice. They can assess your specific situation and recommend a configuration that meets all your needs while staying within budget.

Conclusion

Understanding steel gauge and its impact on barn strength is vital for anyone planning to build or upgrade a metal barn. From structural integrity and weather resistance to cost-efficiency and long-term maintenance, the thickness of your steel plays a significant role in every aspect of the construction process.

Investing in the right steel gauge ensures that your barn remains a sturdy, functional, and valuable asset for many years. It is a decision that influences not just the construction phase, but the overall performance, durability, and satisfaction you derive from your barn for decades to come.